Imago offers production management of books, stationery, packaging, toys, and games for publishing and non-publishing companies from around the world, who want to benefit from our 40 years of expertise and passion.

Global print solutions

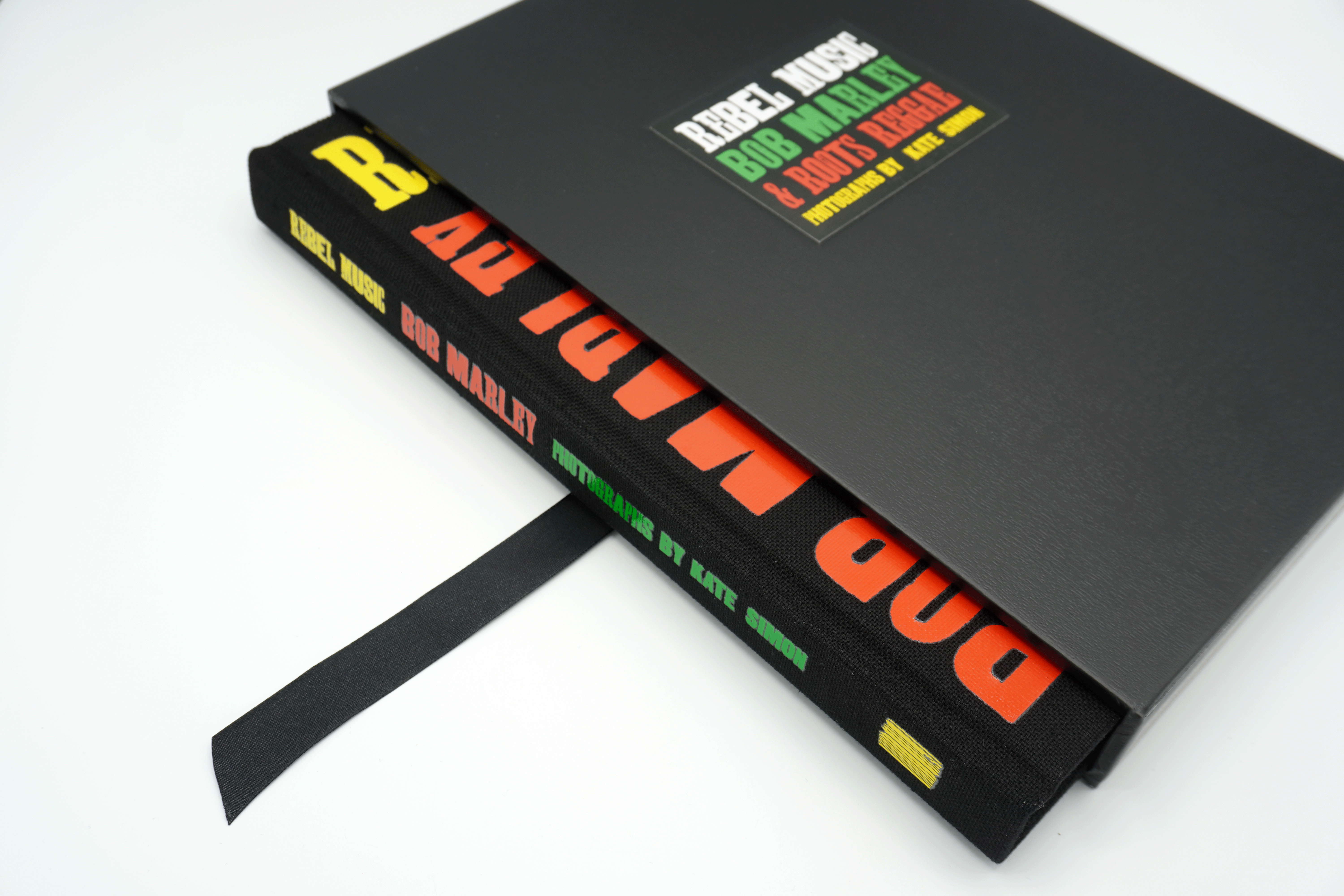

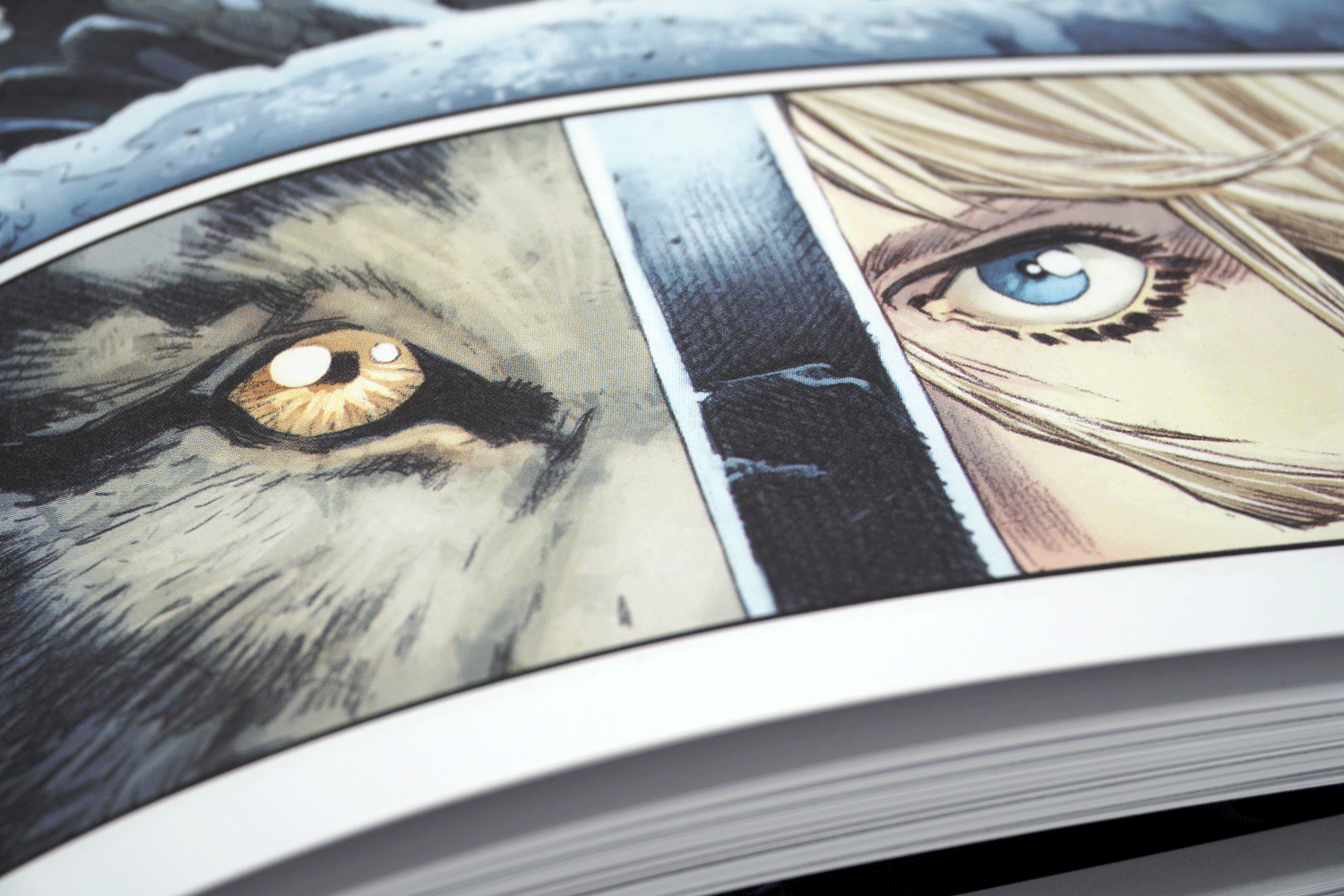

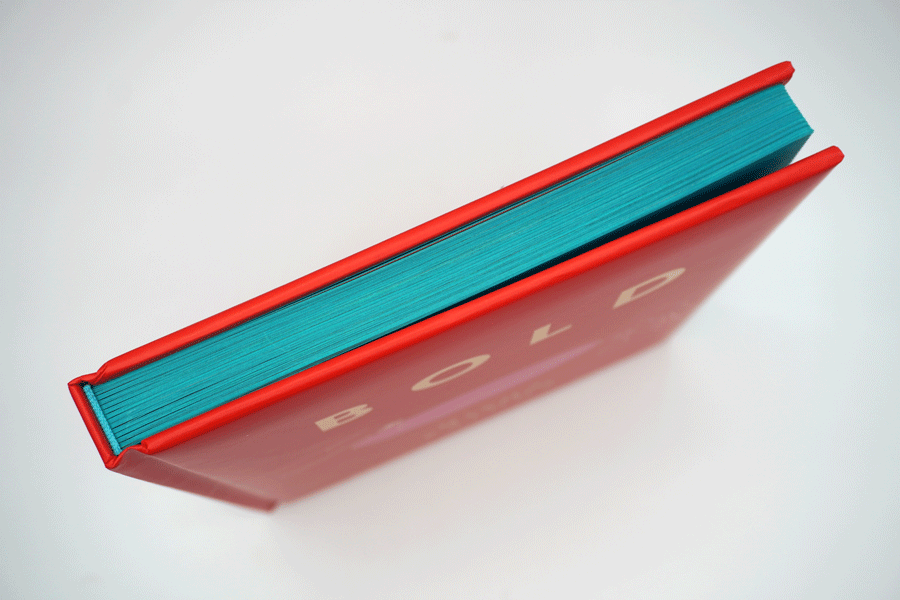

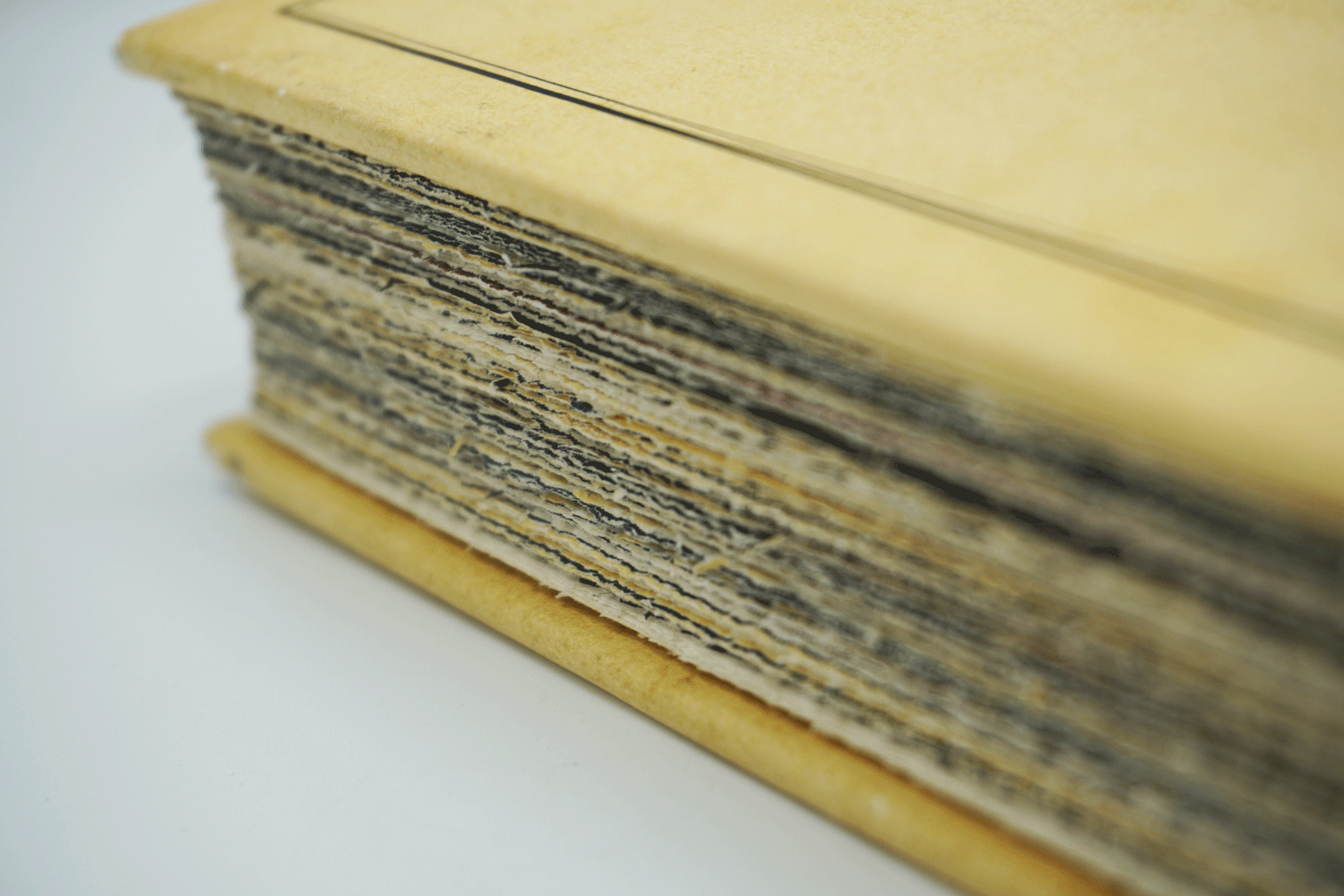

Imago are world-renowned as leaders in print management, creating beautiful print projects including, but certainly not limited to, books, stationery, gifts, calendars, games, jigsaw puzzles, card sets, packaging, marketing materials, and bespoke print projects.

Showreel

Case studies

Client services

Print Management

We can help you choose the best materials for your project including papers, boards, and finishes.

Global Print Services

Having worked with over 1,000 worldwide publishers, we use our knowledge, capacity, and creativity to bring your project to life.

Product Safety & Consultancy

Our industry experts offer consultancy and training to publishers, suppliers, and other businesses.

Get In Touch

If you have any questions about our services or if you have a project to discuss, please get in touch with the team today.

We understand how important it is to uphold the highest ethical standards.

We make sure that the factories producing your projects operate responsibly and ethically, use materials and processes that are safe and sustainable, and that the final product exceeds quality expectations and meets relevant safety requirements.

Create, Print, Source, Deliver

Choosing where and who to print with depends on many factors: price, quality, schedule, proximity, and capability all need to align. That’s where we can help, we’ve done the groundwork and we have the relationships to give you real choices – a truly global printing solution.

I am absolutely delighted and entirely impressed. I’ve been involved in print since 1983, and this is one of the most impressive services I have experienced!

Terry O’Hare, Managing Director

3fiftysixmedia

It means a lot to me that you value this relationship… you and Imago showed that you’re a lifelong business partner.

Brian Thomas, Founder & President

Therapy Games

I just wanted to write to thank you so much for helping us navigate this (quite stressful) undertaking for us at this stage in the publishing life of Little Door Books. Imago have been wonderful, allaying my fears, answering my silly questions, and looking out for us by getting us a good deal so that we have been able to complete the task financially.

Alan Windram, Director

Little Door Books

![]()

Thank you so much for being so amazing and making this work for our client. It means the world having someone like you having our back.

Maria C. Litman

Wordaful

Using Imago has transformed how we do business. With Imago we saved at least 3-6 months of coordination time and I wouldn’t ever go back to ordering from printing companies directly! First class service and amazing support.

Shahbaz Mirza

Towards Faith

![]()

Whenever there has been an issue Imago step up to the plate, communicate clearly and come up with a solution. Their customer relations are second to none. I know we are in the best of hands.

Guy & Daniel Goldwater

Dayworks Design

Start your project

At Imago, we’re dedicated to ensuring your book printing project is handled with care and attention from start to finish.

Get in touch with us today and we will get back to you as soon as possible to discuss your project in more detail.